At Simplifhy, we offer a range of products capable of generating hydrogen and refuelling hydrogen vehicles.

All our solutions are fully customisable according to the needs of the plant:

HYPER-GEN

H2-GEN

H2-POWER

COMPRESSORLESS HRS

The European Union has set short-term and long-term target to achieve a 40% reduction in CO2 emissions by 2030 with respect to 1990 and to achieve climate neutrality by 2050.

In this context, in July 2020 it has been established for Hydrogen a key role to reach both the environmental national target together with a safe and reliable energy production.

Moreover, in the long-term, Hydrogen can support the decarbonization process alongside with other low-carbon emission technologies.

HYPER-GEN

production of electricity from renewable sources

HYPER-GEN is an integrated system to produce electricity that allows you to use only renewable sources.

This solution is used in remote or not accessible sites to the electricity grid and allows the creation of autonomous sites in a totally decarbonised way.

The technical characteristics of the HYPER-GEN solution

HYPER-GEN consists of a container inside which there are modular cabinets capable of generating electricity starting from green hydrogen. The system is equipped with technologies to ensure safe operation, correct use and a remote connection for maintenance and data collection.

Below is the technical information.

Inlet:

- hydrogen from cylinders: purity 99.999%

- consumption of hydrogen according to the required power

- possibility of local production of hydrogen through renewable sources and electrolyser (with storage at 30 bar): optional

Outlet:

- electricity production in AC: from 5kw to 50kw

- hot water at 55 °C

The container that encloses this solution measures approximately 6 meters deep by 2.5 meters wide by 2.5 meters high (20-foot container)

H2-GEN

Hydrogen production

H2-GEN is an integrated solution for Hydrogen production and storage (optional) in industrial processes of small and large companies where hydrogen is already used.

This solution allows industries to reach independency in the Hydrogen production process, hydrogen that is currently coming from hard coal, transported, and delivered through cylinder trailers.

Technical features of H2-GEN

H2-BASIC is a modular cabinet for electrolysis, equipped with technologies to guarantee safety and correct usage. It is complete with a remote connection for maintenance and data collection.

Here below the Technical Specification.

Input:

- power consumption: 2,4 to 9,6 kWh/Nm³

- water consumption: 0,8 l/Nm³ of H₂

Output:

- H₂ production: 0,5 to 2 Nm³/h @ 30 bar with purity from 99,9% up to 99,999%

- H₂ storage (optional)

The cabinet dimensions are: 800 x 800 x 2000 mm (depth x width x height)

H2-POWER

renewable energy conservation

H2-POWER is a system designed to cope with the need to conserve the one’s energy production from renewable sources for long periods and increase energy autonomy.

This solution can be used in remote sites not connected to the main electrical grid as it guarantees constant availability of energy where this is not accessible.

Technical features of H2-POWER

H2-POWER is a modular cabinet including Electrolyzers, PEM Fuel Cell, and collection of the Oxygen. It is ready for external installation, complete with safety technologies and remote connection for maintenance and data collection. This solution integrates the production and storage of hydrogen with electric power generation through the fuel cell.

Here below the Technical Specification.

Input:

- power consumption: 4,8 kWh/Nm³

- water consumption: 0,8 l/Nm³ di H₂

Output:

- nominal power: from 1 to 5 kW

- output voltage: 48 VDC (230 VAC optional)

- autonomy (with standard H₂ storage size): 28 kWh (example: 20 working hours @ 1,5 kW)

Storage:

- standard H₂ storage: 800 l @ 30 barg (2 kg of H₂)

- storage refilling time: 22 hours

- H₂ production: 1 Nm³/h @ 30 bar

The cabinet dimensions are: 800 x 800 x 2000 mm (depth x width x height)

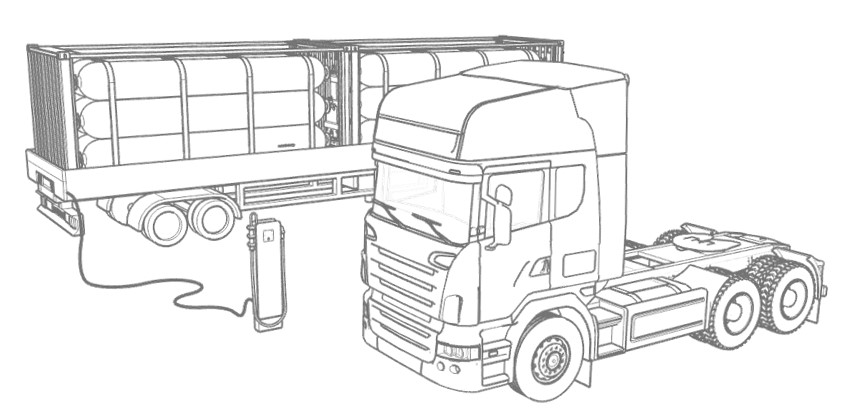

COMPRESSORLESS HRS

refuelling hydrogen vehicles without a compressor

The product consists of a compressorless mobile hydrogen vehicle refuelling dispenser, which allows for a quick and safe supply of hydrogen vehicles in different contexts.

The gas is brought to the site via storage units at 500 bar together with the dispensing system; once at the destination, the two systems are then connected via a hose, and the system is immediately ready to dispense hydrogen.

The dispenser is suitable for connection to different vehicles such as buses, boats or other types of transport.

Once the refuelling process is complete, the system is disassembled and removed, leaving the site untouched.

This system aims to install a hydrogen refuelling system for various purposes such as:

- Temporary, test installations

- Projects requiring installation within a short time frame

- Refuelling stations in remote areas

- Refuelling stations in areas with limited electrical availability and/or space

Technical characteristics of the COMPRESSORLESS HRS

- Electrical power <5kW

- Delivery pressure 350 bar

Want to find out more about Simplifhy products?

We are excited to share the latest news and innovative products we propose.

Download the documents to learn more.